Copper is one of the noble metals that stay resistant to the effects of oxidation, corrosion and atmospheric moisture. Very few metals are as compatible as copper in the manufacturing of the wires and plates. For electrical purposes and conductor manufacturing, copper wires play a major role. Owing to excellent electrical conductivity and resistance to wear and tear makes bare copper wires the first choice in the application of standard metals in the electrical circuits. The use of copper wires is just a few hundred years old. During the 19th century, scientists and engineers discovered the potential of copper wires as an electromagnetic material that can be alloyed as well.

Copper was majorly used as an ornament or as

utensils. The improvement in machining processes harmonized with the

metallurgical improvement ensured that copper climbed ladders of sophisticated

electrical applications in short span of time.

We tell you 3 things that scientist

discovered about copper wires in two hundred years that makes it an amazing

element.

1 Initial use

in transmitting electromagnetic waves

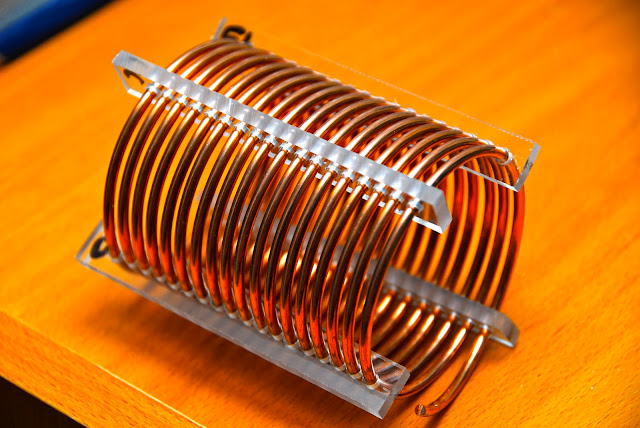

Copper wires have better of both worlds. It

is an excellent electrical conductor as well as magnetic field conductor. It

means it can be used as wire in transmitting signals. Morse code and telegraph

are the best examples of stranded copper wires being used in the modern day

world; finding is origin in the 19th century. The

diversification of the braided copper wires

being used in marine navigation and radio signalling also is the part of

application of electromagnetic waves.

2 Advent of

electricity

Electricity is one of the greatest

discoveries that changed the course of human evolution. From industrial era to the

modern computer era, electricity has played a pivotal role. Copper wires,

especially the bare ones have played a key part in transmitting electrical

signals to remote parts of the world. Carrying the electricity from the

powerhouse, where electricity is produced to homes and industries, is indeed

possible because of the overhead transmitting lines made of braided and bare

copper wires. They have stood against test of time by resisting the harsh

weather conditions. They hardly slacken over a period of time and retain their

physical properties effectively.

3 Copper

wires alloyed with other metals

Stranded and braided copper wires

don’t get hot even during continuous signal processing. It has a commendable

resistance against wear and tear which leads to loss of metal. It has

impressive corrosion resistance that makes it great for use even in bare forms.

That’s exactly the reason why bare copper wires are so popular in the

open-field signal stations. Copper can withstand temperature variations between

-80 degrees centigrade to over 110 degrees centigrade without showing much of a

variance in its physical and electrical properties. It is alloyed with tin,

nickel and other noble metals for glaze and extra insulation. Even in alloyed

form, copper wires are very flexible and can be used in much smaller appliances

with easy installation and replacement possibilities.