Tinsel wire is a type of electrical wire. It is processed and flattened with cadmium copper and silver plated copper. After these processes, the tinsel copper is braided, stranded or twisted to get the final product.

It exhibits mechanical flexibility which is why it is often used in cords made for handsets and telephones. Tinsel’s extreme flexibility makes it resistant to metal fatigue, therefore making it very different from regular stranded wire and solid wire.

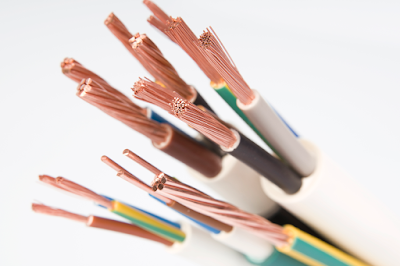

Tinsel wire is made with several thin copper wire strands that are wrapped around a core, usually made from textile. Copper wire is often used because after silver it is one of the best conductors of electricity. However copper is much more reliable and cost effective material for power transfer and manufacturing electronic gadgets and goods. Copper is also the ideal choice for transferring power over short to long distances.

Apart from being used to make electronics and electrical components, tinsel copper is frequently used to make jewellery, utensils and deep-water fishing implements. It is an invaluable alloy in the chemical industry.

The telecommunications industry also makes extensive use of tinsel wire. Apart from telephone cords, tinsel wire is used in telecom cables and speakers. The tinsel wires in these applications are made from electrolytic-grade copper foils that are annealed. Copper wires are then wrapped along a textile core or nylon thread. This lends resistance to breaking and extreme flexibility to tinsel copper wires.

To make a wire to wire connection, you simply have to connect these wires with one another by piercing through the covering. You are not required to strip the insulation.

Tinsel copper wires are used by electricians, electrical engineers, product designers and technology developers.

To learn more about tinsel copper wires or to place your order today, please visit Ganpati Engineering.