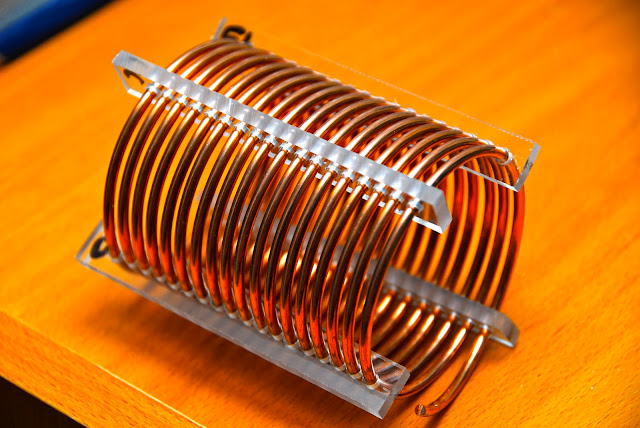

Braided flexible copper flat wires have superior conductivity. Since they prevent a considerable amount of heat loss from occurring, they are a preferred metal for diverse applications. Braided copper wires get less messy than regular wires and can be rolled into square or rectangular shape from a round-shaped roll.

What are the benefits of using braided flexible copper flat wires?

What are the benefits of using braided flexible copper flat wires?

Dependable

This type of copper wire is both sturdy and flexible. This type of wire has improved conductivity and is easy to use in application. As a result, there are fewer wiring errors and minimal breakdown occurrences.

Lightweight

Lightweight

Flat copper wires are sturdier than their round counterparts, therefore they don’t require fillers, tapes or insulation material to be used alongside.

Space Saving

Since tapes and fillers are not required during installation, flat copper wires don’t take up much space. Stacking flat wires is far simpler because they have a square or rectangular cross section.

Strong and Flexible

Space Saving

Since tapes and fillers are not required during installation, flat copper wires don’t take up much space. Stacking flat wires is far simpler because they have a square or rectangular cross section.

Strong and Flexible

Flat copper wires are often turned into insulators and conductors and are therefore capable of handling tensile loads. The flat shape and added flexibility of copper improves its use in applications that require high flexing such as in doors, drawers and rotating arms to name a few. Flat fires can bend easily, reach high held locations and do not require fastening during installation. It also facilitates locking and attachment.

Widely Used in Several Applications

Widely Used in Several Applications

Copper is known for possessing excellent electrical and thermal conductivity. It is used in many applications and has been transformed into many versatile uses by wire manufacturers. This form of copper wiring may be used in light fixtures, printers, computers and a wide range of other electronic devices.

Flat copper wires can also withstand water, heat and humidity. They are highly useful in automobile and marine applications, i.e. ship building.

Non Industrial Applications

Flat copper wires can also withstand water, heat and humidity. They are highly useful in automobile and marine applications, i.e. ship building.

Non Industrial Applications

The shiny appearance of copper lends itself to non-commercial and non-industrial uses such as jewellery crafting, fishing line production, particularly for deep sea fishing, etc.

Different Forms

Different Forms

Apart from braided flexible, copper wires can be transformed into plated, stranded and coated. Copper wires can be used for applications in the sea and land.

To learn more about braided flexible copper flat wires or to place your order, please visit Ganpati Engineering.