1. True Concentric

These wires have a central copper wire. This core is surrounded by a successive layers of alternately arranged strands with the length of each layer slightly larger than the successive layer. The lay direction is established by the twisting of the machine during the stranding process.

The lay length in these wires keep reducing as the layers are added to the inner strands.

2. Equilay

Also called as equally laid concentric cables, these stranded types of copper wires have helically arranged strands. The lay length is consistent unlike that in the true concentric strands. Rest of the features are same as that of its true sibling.

3. Unidirectional

This is a special case of concentric stranding where the helically laid strands are laid in the same direction with increasing lay length. These configurations allows the conductor cable to be laid in a tight geometry with lowest tolerance for diameter variations throughout the length of the wire.

The wires are preferred for motors and transformers featuring in the high torsional simulations, like in automated production lines or in robotics. In short, it is easy to classify unidirectional stranded wire cables as “Robotics Cables”.

4. Rope

Rope stranding is also a type of stranded wire configuration where the strands of copper wires are arranged in a circular manner mostly comprising of 7 or 19 members. It is witnessed that the Rope stranding has the highest twisting and bending flexibility compared to other stranding mechanisms. The advantage of using Rope stranding is that the manufacturer can add successive layers of strands without compromising on the diameter tolerances, already fixed for the appliance.

Identification of Stranded Cables

Stranded cables are extensively used as Power cables and Submersible winding wires. Depending on the laying of the wires, they are classified into three families.

- Class B Power Cables

- Class C with higher flexibility quotient than Class B stranding

- Class D with highest flexibility, accommodating additional layers of stranding within diameter tolerance limits

Another classification of the stranded copper cables is done on the basis of rope layout and the kind of application it is employed in.

- Class G covering the Portable winding wires

- Class H Enamelled copper wires with polyesterimide insulation for better flexibility

- Class I cables for motor leads

- Class K stationary cables for cord and winding of No. 30 AWG wires

- Class M No.34 AWG Constant service

There are other braided varieties of the copper wires that more or less add extra level of robustness into the configuration. They are:

- Loaded twisted pair with extra inductance, used in load coils

- Bonded pairs

- Ribbon cables for connectors and printed circuit boards

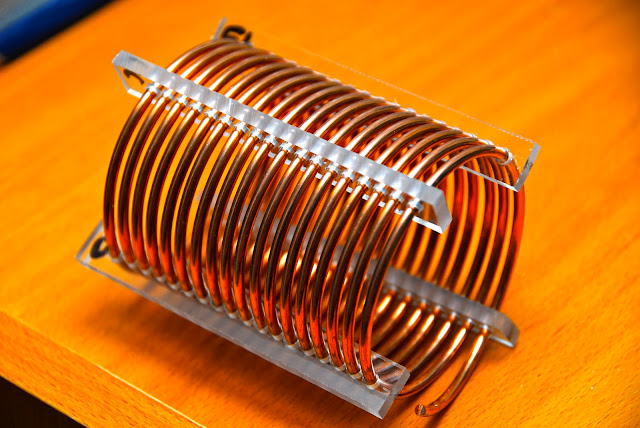

Litz Wires

Extensively used in electronic circuits, Litz wires are insulated strands of thin copper wires woven or twisted around each other to reduce the Skin Effect and Proximity Effect.

They are used in transformers and inductors operating at high frequencies.