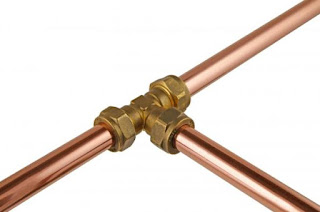

Copper Plumbing fittings are the first choice of building contractors and homeowners. They are used in offices, homes, schools, colleges in short you will find them in every place. The reason is the trust it has developed over the years. The copper pipes are known for the high quality and durability. Let us take a look at the top advantages of using copper plumbing fittings in residential as well as commercial projects.

1. Affordable:

It comes up as the most affordable plumbing material. When you compare it with other material available in the market then you will find that you are getting high quality material at a very competitive price.

2. Increase Resale Value:

The home with copper plumbing fittings will help you get good resale value. The buyer knows that copper fitting means reliability. They know that they don’t have to incur any expense on them if they buy the house. Hence, it is advantageous to both seller and buyer.

3. Enhances Performance:

The premium quality copper pump enhances the performance of the plumbing system. It is one of the materials that gives you trouble free performance for years. It hardly requires any maintenance and continues to give incredible performance for years.

4. Durable:

When it comes to durability, copper wires beats other materials hands down. It is resistant to corrosion and harmful ultra violet rays. The copper pipes scores here as these are two most common reasons for wearing of water fitting system. Another remarkable feature is that it remains unaffected with variations in water pressure. The climate also doesn’t have any effect on it. These fittings doesn’t become fragile and break with time. Also, there is no probability of crack. The copper wires easily lasts for decades, it gives you trouble free performance. The only thing you need to make sure is that you get the plumbing done from a professional plumber.

5. Fire Resistant:

The copper pipes are fire resistant. In case of fire it will not melt, break or burn. It can easily withstand the toxic gases released during the fire. It is a big plus point because others made of plastic will not only melt but can also suffocate the occupant of the home. Safety of near and dear ones is always a priority so you can trust copper fitting completely here.

6. Easy to work:

The plumbers around the world love copper pipes as it is easy to work with. It can be easily bend during the installation. It means the less need of fasteners and other joints. This reduces the installation cost.

7. Recyclable:

Copper is easily recyclable hence it is environmental friendly. It is hundred percent recyclable. If you support go green then it comes up as the best option. Although, the question of recycling only comes up when it wears off but that is rare, as it easily last for 50-years.

8. Completely safe:

The copper pipe doesn’t possess any health threats. It doesn’t rust like iron pipe or melt at high temperature like plastic pipes. It will give you hygienic water without maintenance for years. It also keeps contaminants away from the water supply system. It is completely safe for your family.